|

Modification

of a 100W 2,1GHz PA for 2,3GHz

Typical data on 2,3GHz after modification :

Gain: 9-10dB, Output power 100-120W

Active device is

Motorola MRF 21120

VDD 28V at 10A, bias +12V.

MRF21120 is a Gemini enhancement LDMOS transistor. It has a power

gain of typically 10 dB at 2,1GHz and about the same performance is

possible on 2,3GHz, but some adjustment is needed to squeeze the last

couple of tenth of dB out of the transistor. This PA was

originally made for 2,1GHz. It is a cut-out

from its original board. The VDD is +28V

and the bias input is +12V.

For full performance, a good size heat sink must be used. If the

temperature on the transistor wafer is allowed to rise above about +100

degrees Celsius, the LDMOS will reduce gain up to several

dB. If the heat sink is too warm, a fan must be used to cool the heat

sink.

Make sure that you have terminated both input and output into 50 Ohm

Then adjust each half of the Gemini to 0,8A idle current with no RF drive

applied. This assures linear operation of the PA.

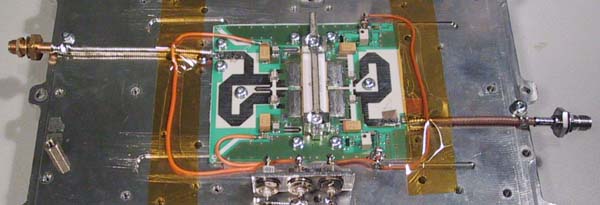

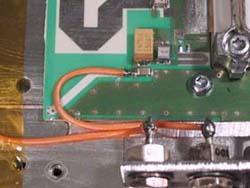

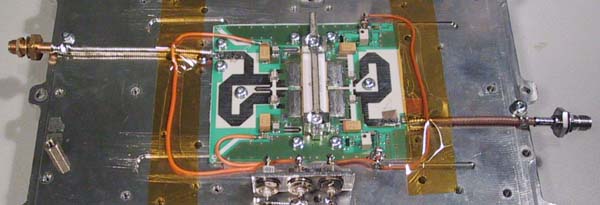

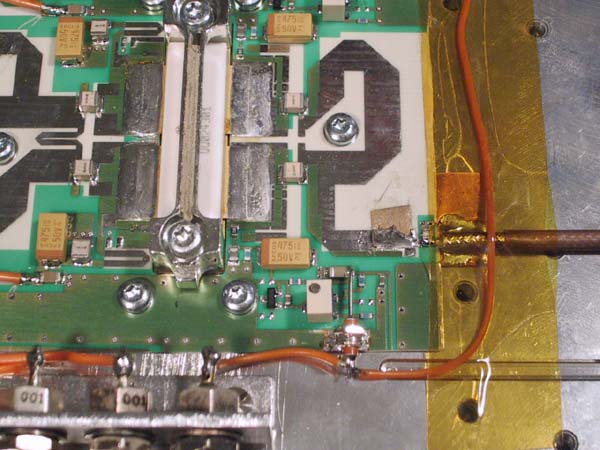

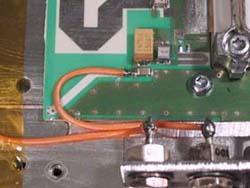

It is very important that you provide a

perfect ground at your input and output terminals of the PCB. In this

example, a small piece of copper sheet is soldered on the heat sink side

of the PCB under the input and output terminals. The sheet is protruding

outside the PCB, thus providing a ground pad for the connecting coax

cable. Please note the nonexistent length of centre conductor from the

coax at the soldering point of the PCB.

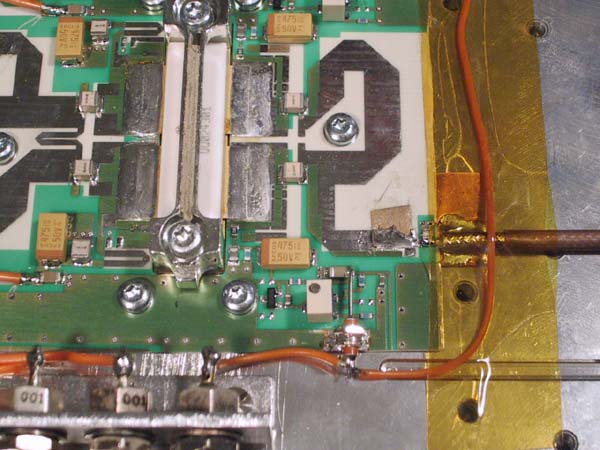

In the original, the input match is not

at optimum on 2,3GHz. This can easily be adjusted by increasing the pad

size close to the input on the PCB. The pad showed here may not

necessary be the same size on your board as it is an unique adjustment

for each PA. About one dB was found, bringing the

gain on 2,3GHz from 8,5 to 9,5 dB on this sample PA.

To provide a PTT line, a relay or similar can

remove the +12V bias. The idle current will then go to zero without need

to remove the VDD when PTT is in RX.

|

When you connect VDD to the PCB,

take care not to short it to ground as one end of the trace is

feed to the heat sink side of the PCB. In the PA used here, I have

cut of the copper trace close to the decoupling capacitor and

soldered the VDD cable close to the capacitor

(the orange cable). |

|

Make

sure that the transistor has a slot 1,3mm deep to allow the PCB to be

absolutely flush with the heat sink. All provided screws holes must be used

if you want the available power into your output coax. All

microwave design rules apply!! A note of caution, to not drill out

the through plated holes in the PCB, to make room for bigger screws

than the original size of 2,5mm. |

For a 400W PA see the OH3LWP solution

http://oh3tr.ele.tut.fi/~ftp/pa/13cm_400W_LDMOS_PA/

|